tapered end mills are used for

A solid carbide tool used primarily in the mold tool and die industry as a solution to mill. Tapered end mills are used on CNC or manual milling machines for die- and mold-machining.

All 12 degree tapered end mills listed below are grouped by angle per side.

. Outstanding for high precision milling deep within a part often one of the most challenging applications a machinist faces. Conical Tool Company LC-208 30 LHS-RHC HSS Tapered End Mill - 3 Flute x 18 Tip x 03346 Large Diameter x 38 Shank x 2 Length of Cut x 4 14 Overall Length. They are used specifically for designed parts that require an angled side wall.

Order today with free shipping. Ideal for use in die cast dies molds. TAPERED HIGH SPEED STEEL.

The mills are single ended with three flutes and have a square end. For ultra-deep milling within a part Long Reach Tapered End Mills are optimized to deliver pinpoint accuracy. The taper naturally produces positive relief.

Engineered for excellent performance in light profiling and finishing applications this 5 Flute Variable Pitch End Mill has a tapered profile designed to use in mold and die pockets and other tapered wall applications. Cutters were 130 each minimum 3 pcs so 390 total. In CNC machining taper end mills are used in many industries for a large number of applications such as walls with draft or clearance angle tool and die work mold work even for reaming holes to make them conical.

These 15 degree tapered end mills have a 15 degree taper per side. The tapered profile of this Helical Solutions End Mill is engineered for optimal performance in light profiling and mold and die finishing applications. Tapered End Mills cut and machine a wide range of materials from soft Plastics Aluminum to harder materials such as Steel Stainless Steel and Titanium.

Tapered End Mills have flutes on their cutting head that carry chips away from a workpiece to prevent damage to the end mill or workpiece. Tapered end mills create slots or grooves with tapered walls in a workpiece. Ad Fully Stocked in 05 to 15 Tapers.

They are three flute square end with a 30 helix. Use these end mills for general purpose work in most material such as aluminum brass bronze iron and steel. Fully stocked in 4 and 5 flute options with a variable pitch geometry for reduced harmonics and increased feed rates this tool is coated with our Aplus coating for improved tool life and increased edge strength.

If the were taper reamers for taper pins than they would be marked with the taper like 150 for metric or Taperft for imperial and would most likely have only a slight twist or none at all. They are used specifically for designed parts that require an angled side wall. Tapered profile designed for use in mold and die pockets and other tapered wall applications.

A tool with a tapered neck will offer an increasing cross section resulting in less tool deflection and increased strength over straight reach options. The author indicates that cone drills are cheaper than tapered end mills but they also seem to be less common. Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece.

Ad Enjoy Discounts Hottest Sales On Tapered End Mills. When i get to look at it ill post pictures. Ball Nose and Square Tapered End Mills produce tapered walls grooves and holes when cutting and machining.

Conical mills are available in angles of 5 1 15 2 3 4 5 7 10 and 15 degrees TPS. Making gears with this type of cutter would. Ball Nose End Mill Assorted R075 Tip 18 Tapered End Mill TiAlN Coated CNC Router Bits Carbide Bit CNC Cutter for Carving Engraving.

This section covers the applications of both flat and ball types of tapered end mills in standard two dimensional. HTPR-5 Carbide End Mills. Using Tapered End Mills.

They have a conical cutting head that is wider at the base than the tip. Stocked in Flute Counts from 3 to 14. Ad Built for Tough Materials up to 65Rc.

These End Mills are useful for a wide range of applications including tool and die work reaming conical holes and other machining operations that need an angled surface. Carbide Tapered End Mills. Used a topnotch ntp3r insert ground to 130 tip flat at a cost of 130 for holder and insert and about a half hour to grind.

For example see here. 440 rows Our Conical Tapered Carbide end mills feature advanced variable geometries to reduce. They are used in several die and mold applications.

Available in Diameters from 015 to 250. Up to 8 cash back Tapered end mills are steel cutting tools and are designed for side milling contouring and machining angled slots. These milling tools produce grooves holes.

I have read descriptions of tapered end mills being used to make single-tooth gear cutters. All are center cutting allowing plunge cuts into a surface. Solid carbide models are 100 precision ground and inspected to insure complete uniformity and reliability required in the precision mold industry.

Square Ball Nose To Cut Tapered Walls. They are used to cut a die taper on the bottom of a perforating die so the slug can fall out and not jam the hole in a die block. Cutters of course cheap.

Taper mills or conical mills produce grooves holes or milled sides with a sloped angle. Tapered End Mills are center cutting 3 flute high speed steel tools designed for side milling contouring and machining angled slots. Get the Deals now.

Could have saved about 125 hours using a 60 degree included angle end mill with 130 minor diameter. Also known as taper degree end mills theyre often used to machine angled slots in dies and molds. With the widest selection of high speed steel tapered end mills available and an average 998 in stock status the Conical Tapered High Speed Steel end mill is the go-to tool for unique machining challenges.

Jan 18 2022. Tapered end mills are designed with a cutting edge that tapers at the end. When considering an end mill with a straight reach versus the same end mill with a slightly tapered reach there are clear gains in tool performance and productivity.

Endmill Selection Guide Redline Tools Redline Tools

3 175 42mm Taper Ball Nose End Mills Tap Cnc 2 Flutes Cone Bits Solid Carbide Coated Tapered Milling Cutter End Mill Cool Things To Buy Milling

Doing High Speed Milling Of Aluminum Alloys Take A Look At Osg S Aero End Mill Series Http Bit Ly 1v0xere Osg Osg End Mill Metal Working Aluminium Alloy

Router Tool Cnc Router Router Bits

Ball End Mills Fastenal Canada

Shars Com End Mills Made In Usa

End Mill Cutters End Mill Cutters Milling Technology Emuge Franken Website

Pin On Cnc Foam Milling Router Bits

Common Types Of End Mills 3 1 Voxel Based Mrr Expression Of The Download Scientific Diagram

Osg Taps End Mills Drills Indexable Composite Tooling Diamond Coating Die Products Osg Cutting Tools For Milling Applications

Pin On Cnc Foam Milling Router Bits

8 Ways You Re Killing Your End Mill In The Loupe

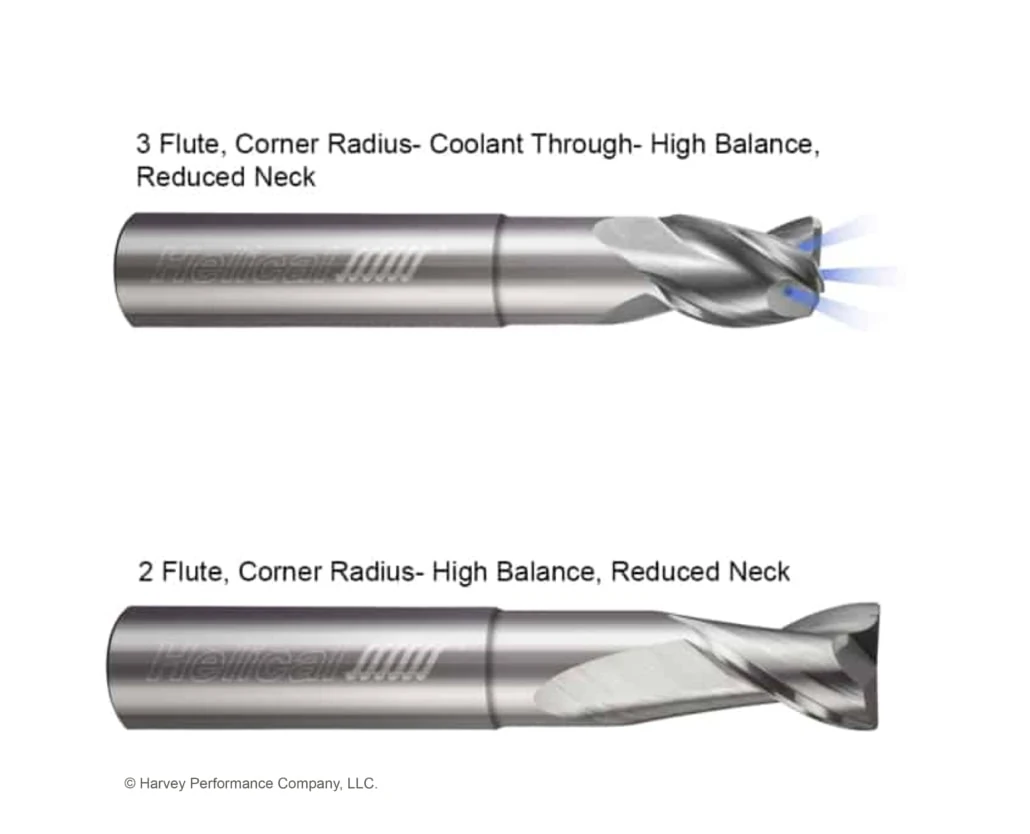

Necked Tooling Archives Harvey Performance Company

Basic End Mills Technical Information Msc Industrial Supply Co

1pcs R0 75 D6 30 5 75l 2f Solid Carbide 6mm Ball Nose Tapered End Mills Router Bits Cnc Taper Wood Metal Milling Cutter Cnc Router Bits End Mill

25 Lot Of Vintage Machinist Tools Lathe Bits End Mills Countersinks C1541 Ebay Machinist Tools Tools End Mill

Types Of End Mills Difference Between End Mill And Drill Bit What Is End Milling Cnclathing